ruzki

Member

Hi!

my Name is Georg, I'm from Germany and new in this forum.

I would like to introduce myself by showing you my last Megane F7R T turbo conversion project.

I have sold this car 3 years ago but since this forum is named "turborenault.co.uk" I thought this car will fit good in here.

Since it is quite difficult to get a turbo conversion legal here in Germany, I've tried to achieve a OEM´ish look as possible.

I drove this car for approx 20k km with this Turbo and had no problems what so ever.

Technical Data:

- Engine F7R 710 stock

- ECU custom to fit in the original Siemens housing

- Turbo Garrett TB2804 because big turbine housing ar 0.86 good with stock compression ratio basically this is the largest T28 Turbo

- Clutch Helix 8 or 6 pad sinter .. not sure anymore

- Boost 0.9 bar

- hp don't know .. I think around 275hp

- exhaust manifold custom made out of stainless steel .. designed with CAD

- Downpipe 63,5mm stainless steel

- Catalytic converter (very important for me .. i don't like exhaust smell) 200 psi metal oval shaped for maximum possible size

- Exhaust Bastuck 63,5mm all the way with oval end tip .. oval look best on Megane I .. fact!

- 280mm brakes .. stock 262mm in Europe

- stock spring and dampers

- Megane DTI Intercooler

- some intercooler pipe from Megane DTI and DTI air filter housing

Engine bay

ECU.. one of the first versions

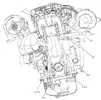

Turbo manifold

my Name is Georg, I'm from Germany and new in this forum.

I would like to introduce myself by showing you my last Megane F7R T turbo conversion project.

I have sold this car 3 years ago but since this forum is named "turborenault.co.uk" I thought this car will fit good in here.

Since it is quite difficult to get a turbo conversion legal here in Germany, I've tried to achieve a OEM´ish look as possible.

I drove this car for approx 20k km with this Turbo and had no problems what so ever.

Technical Data:

- Engine F7R 710 stock

- ECU custom to fit in the original Siemens housing

- Turbo Garrett TB2804 because big turbine housing ar 0.86 good with stock compression ratio basically this is the largest T28 Turbo

- Clutch Helix 8 or 6 pad sinter .. not sure anymore

- Boost 0.9 bar

- hp don't know .. I think around 275hp

- exhaust manifold custom made out of stainless steel .. designed with CAD

- Downpipe 63,5mm stainless steel

- Catalytic converter (very important for me .. i don't like exhaust smell) 200 psi metal oval shaped for maximum possible size

- Exhaust Bastuck 63,5mm all the way with oval end tip .. oval look best on Megane I .. fact!

- 280mm brakes .. stock 262mm in Europe

- stock spring and dampers

- Megane DTI Intercooler

- some intercooler pipe from Megane DTI and DTI air filter housing

Engine bay

ECU.. one of the first versions

Turbo manifold