There is more to life with TurboRenault.co.uk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How (not) to make your Dauphine Handle

- Thread starter Steve Swan

- Start date

Steve Swan

Well-Known Member

I think you are right, I will need to rig up a couple of flying leads to a multimeter and watch it on the road. It is not the usual thing you are referring to it is a faint slow rhythmic pulse. It's kinda Funky like it was alive! You know how early test drives are, your brain going 100 miles an hour trying to analyse every sound and watch everything at once. I should be able to start concentrating on specific areas now I know it is all basically behaving. In fact I have an ETB Digidash 2 in it which will show voltage in real time I think, so I should rig up leads from the rear end to a multimeter and be able to check voltage at both ends of the car.

DaveL485

Staff member

My old Volvo did that too, was the voltage fluctuating, figured it must have been the regulator on the alternator. It stopped doing it when I changed the alternator.Its like the voltage is wandering a volt or 2. never seen anything like this before, not like the usual thing cars do at idle this has a steady rhythm. the lights are all stable at idle

Only did it at idle, not when the revs were up.

Steve Swan

Well-Known Member

Steve Swan

Well-Known Member

KiwiGordini

New Member

What a fantastic read!

If it's any use I have a local spline cutter in Tamworth as I see you mentioned having lost yours.

If it's any use I have a local spline cutter in Tamworth as I see you mentioned having lost yours.

Steve Swan

Well-Known Member

@KiwiGordini . Thanks for that, glad you're enjoying it. Is that Tamworth in Staffordshire UK, or is it Tamworth somewhere very far away????

KiwiGordini

New Member

Tamworth Staffordshire.

Steve Swan

Well-Known Member

Hello all

Sorry for the silence, but I have been busy fixing gearboxes and all the other boring stuff that spoils all your fun when you are a grown up. I need to get back in the groove and get back to it. I have been meddling around with the Dauph and managing to put more things on the snagging list rather than taking them off. If anyone can point me to a good supplier of CDS tube in 3 m lengths (or would be prepared to cut a 6m in two) and will post to Scotland please let me know . In other news I am trying to find a 38Tooth 1st gear from a 365 Renault transaxle, again if any one can point me in the right direction I would be eternally grateful

More nonsense to follow

Sorry for the silence, but I have been busy fixing gearboxes and all the other boring stuff that spoils all your fun when you are a grown up. I need to get back in the groove and get back to it. I have been meddling around with the Dauph and managing to put more things on the snagging list rather than taking them off. If anyone can point me to a good supplier of CDS tube in 3 m lengths (or would be prepared to cut a 6m in two) and will post to Scotland please let me know . In other news I am trying to find a 38Tooth 1st gear from a 365 Renault transaxle, again if any one can point me in the right direction I would be eternally grateful

More nonsense to follow

Steve Swan

Well-Known Member

Steve Swan

Well-Known Member

Steve Swan

Well-Known Member

I've been a bit quiet on here of late trying to solve a problem that was defying me whilst hiding in plain sight.

After writing this up, it was time to start driving the car and de-bugging it. It feels like it has real potential its quite fast with only 130 bhp due to being about 760kg all up ( without driver obviously as he is the heaviest part of the vehicle)

It did however have the irritating tendency to want to turn left all the time. It has other issues (voltage reg and poor gearshift) but It is not possible to zone in on these whilst you have to concentrate on the steering at all times. I had a quick check of the measurements and it was all as it should be. I tried a few obvious easy things like swapping to another set of wheels and tyres , No change, experimented with different toe settings, No change Tyre pressures, No change. Now pretty pissed off I hauled the gearbox out of it to modify the detent mech to improve the gearchange feel. It fought me every step of the way, but I won in the end and confirmed that the back end was also square. Road test, No change. Super pissed off I raised the front and removed the wheels and started to physically measure as many of the suspension components and mounting points as is possible. There are tiny discrepancies a mm here and there, nothing out of the ordinary, as I lay on the floor I thought back over this thread and the steps I had taken to square the Chassis geometry up. One point I remembered was that I had a discrepancy on front camber of 0.2 degree, due to the floor being slightly off. Now all of these checks are always carried out with any anti-roll bars disconnected (which I had) Then once the car is all settled on the floor the roll bar is reconnected so as to be at zero preset (the driving links are free to rotate with thumb and forefinger which they were)

Hang on. They are, but the floor ain't flat, measure the links and the n/s link is 3mm longer than the o/s. Imagine what is happening on a flat surface. The bar is trying to hold the n/s wheel up in the air by 3mm. Will this be the problem?? The pull is pretty bad, can't really see 3mm making that much odds to it. Adjust the links, roadtest and F--k me the issue is about 90% gone it still drifts left, but that is mainly due to road camber as every other vehicle I have driven over the test route in the last 2 weeks also does this. I am now tempted to think that I can bias it out by Lenghtening the o/s link forcing the n/s wheel to share a bit more of the load.

SO a cautionary tale to all you modifiers when you decide to remove all the rubber from your suspension. 3mm may make a very big difference indeed.

Malcolm my Son can't really get his head around driving this. He cannot believe that a car can have such direct steering response. I told him to drive it along the road at 30mph in 4th and just turn it into the Private road where I keep the car which is about 12 foot wide it took him about 4 attempts to do it as there is a particularly nasty Strainer post and a hole in the apex of the turn in point ( so you can't cut it)

This cannot be done in a standard car at that speed, but the Dauph just changes direction. I will need to take it to the old airfield for an understanding of what will happen next . I tried a turn off the road into a very wide clear sighted side road at 60 and it just did it. Kinda freaked me out. The only thing I have driven that felt like this was a Mate's Mallock mk 19 many years ago. I suspect that the limit will appear very late and quite violently, So this rusty old man will need some practice.

Happy motoring Drive safe

After writing this up, it was time to start driving the car and de-bugging it. It feels like it has real potential its quite fast with only 130 bhp due to being about 760kg all up ( without driver obviously as he is the heaviest part of the vehicle)

It did however have the irritating tendency to want to turn left all the time. It has other issues (voltage reg and poor gearshift) but It is not possible to zone in on these whilst you have to concentrate on the steering at all times. I had a quick check of the measurements and it was all as it should be. I tried a few obvious easy things like swapping to another set of wheels and tyres , No change, experimented with different toe settings, No change Tyre pressures, No change. Now pretty pissed off I hauled the gearbox out of it to modify the detent mech to improve the gearchange feel. It fought me every step of the way, but I won in the end and confirmed that the back end was also square. Road test, No change. Super pissed off I raised the front and removed the wheels and started to physically measure as many of the suspension components and mounting points as is possible. There are tiny discrepancies a mm here and there, nothing out of the ordinary, as I lay on the floor I thought back over this thread and the steps I had taken to square the Chassis geometry up. One point I remembered was that I had a discrepancy on front camber of 0.2 degree, due to the floor being slightly off. Now all of these checks are always carried out with any anti-roll bars disconnected (which I had) Then once the car is all settled on the floor the roll bar is reconnected so as to be at zero preset (the driving links are free to rotate with thumb and forefinger which they were)

Hang on. They are, but the floor ain't flat, measure the links and the n/s link is 3mm longer than the o/s. Imagine what is happening on a flat surface. The bar is trying to hold the n/s wheel up in the air by 3mm. Will this be the problem?? The pull is pretty bad, can't really see 3mm making that much odds to it. Adjust the links, roadtest and F--k me the issue is about 90% gone it still drifts left, but that is mainly due to road camber as every other vehicle I have driven over the test route in the last 2 weeks also does this. I am now tempted to think that I can bias it out by Lenghtening the o/s link forcing the n/s wheel to share a bit more of the load.

SO a cautionary tale to all you modifiers when you decide to remove all the rubber from your suspension. 3mm may make a very big difference indeed.

Malcolm my Son can't really get his head around driving this. He cannot believe that a car can have such direct steering response. I told him to drive it along the road at 30mph in 4th and just turn it into the Private road where I keep the car which is about 12 foot wide it took him about 4 attempts to do it as there is a particularly nasty Strainer post and a hole in the apex of the turn in point ( so you can't cut it)

This cannot be done in a standard car at that speed, but the Dauph just changes direction. I will need to take it to the old airfield for an understanding of what will happen next . I tried a turn off the road into a very wide clear sighted side road at 60 and it just did it. Kinda freaked me out. The only thing I have driven that felt like this was a Mate's Mallock mk 19 many years ago. I suspect that the limit will appear very late and quite violently, So this rusty old man will need some practice.

Happy motoring Drive safe

DaveL485

Staff member

Only one way to find out.I suspect that the limit will appear very late and quite violently,

Video it please

Steve Swan

Well-Known Member

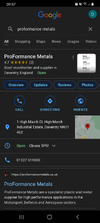

Where does the time go! If you know, let me know. Nothing much happening here except the usual 3 steps forward and 2 back. I need to swap out the alternator as it is not holding a steady output, bit of a pain as it was a new item, but from 10 years ago, the problems of buying things and not using them. I still have a slight drift to the left on the road, but I am sure it is just the car being sensitive to road camber as the problem comes and goes depending on the road. Managed to clip the Z bar bracket against the road and bent it out of shape, this was accomplished by turning sharp left up a steep hill which had a sleeping policeman type bump in the road I did not see. I have decided on a MK2 variant which has a lower profile and will be about 10mm higher than the old one. This is a billet Alloy job, so a piece of Ally plate was procured and I paid a visit to the local Glass merchants who have a water jet cutter with a drawing. The result is fantastic and the price was very reasonable for the work done See below

Much tidier than the originals

Much tidier than the originals

Steve Swan

Well-Known Member

Having had those bits cut out I had a lightbulb moment, I have a damaged set of close ratio gears I have been meaning to sort for some time, well about 15 years, so back to the waterjet with some bits and I think I have a plan, maybe not a good plan, but it's the only one I've got

Take the damaged close ratio 1st gear and waterjet the centre out of it, then turn down a standard 1st gear and shrink and weld the parts together. Maybe it's me that needs the Shrink!!! Tony Dalmolin used to do it all the time, so that's my excuse.

I think the inner and outer diameters will need finished on the cylinder grinder for accuracy then shrunk together.

Take the damaged close ratio 1st gear and waterjet the centre out of it, then turn down a standard 1st gear and shrink and weld the parts together. Maybe it's me that needs the Shrink!!! Tony Dalmolin used to do it all the time, so that's my excuse.

I think the inner and outer diameters will need finished on the cylinder grinder for accuracy then shrunk together.

Similar threads

- Replies

- 8

- Views

- 191

- Replies

- 3

- Views

- 93