Info like this is internet gold. Thanks very much for postingBeen hibernating up here recently. Was scraping the car windows before going for the shopping yesterday at 8.30 and the temp gauge was saying minus 7 ! Wondered where my fingers went.

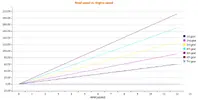

Have been reading up on others threads and was looking in at @Adey for his proposed transplant and was looking at his gear ratio options. Rather than clog his thread up with rubbish I thought I would post the Dauph's numbers here. They are not ideal, but the best compromise that can be worked out from production parts on 300 series based boxes.

I have set the shift point at 7500rpm as a median as you would use 5500 on the road and the full 8000 in the first 3 gears on the track (dependant on circumstances wet or dry how many metres to the next brake point)

Axle ratio is 9x34 3.77:1 1st is 3.41:1 2nd is 2.25:1 3rd is 1.61:1 4th is 1.21:1 and 5th is 0.97:1

There is more to life with TurboRenault.co.uk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How (not) to make your Dauphine Handle

- Thread starter Steve Swan

- Start date

Steve Swan

Well-Known Member

yeah no worries, this is the site i use to plot it Ratio Calculator - Gearboxman

negligible difference in rolling radius

negligible difference in rolling radius

DaveL485

Staff member

And now archived forever in a place everyone can find itInfo like this is internet gold. Thanks very much for posting

@Steve Swan 141mph flat out, will you have the power to get there? Will you have the BALLS to get there?

Steve Swan

Well-Known Member

@DaveL485 It should theoretically get there. My 8 was heavier, a less slippery shape and had 175 bhp 1550cc it would get to 7500 in 5th easy enough (about 120- 125mph) and it felt Ok-ish. I would not want to have to take avoiding action at that speed.

The Dauph was conceived as a long track car, Sliverstone, Brands, Spa etc. My intention had been to do some of the classic sports car club races sharing the driving with Liz to keep cost down, so I gave it the longest legs I thought practical, and it is about 80kg lighter than the 8 and I,m hoping for 190-200 bhp with the 1700 and the very last part is to make a false ally floor to make it a bit more aerodynamic and kill some of the lift it will generate.

As to the last bit of the statement Who knows !- not me. I know I am not really the man I used to be.

I always wanted to take it to Brighton Speed trials and when I spoke to some of the officials from Brighton and Hove MC they were quite interested in the uniqueness of the car. Never say Never Eh!

The Dauph was conceived as a long track car, Sliverstone, Brands, Spa etc. My intention had been to do some of the classic sports car club races sharing the driving with Liz to keep cost down, so I gave it the longest legs I thought practical, and it is about 80kg lighter than the 8 and I,m hoping for 190-200 bhp with the 1700 and the very last part is to make a false ally floor to make it a bit more aerodynamic and kill some of the lift it will generate.

As to the last bit of the statement Who knows !- not me. I know I am not really the man I used to be.

I always wanted to take it to Brighton Speed trials and when I spoke to some of the officials from Brighton and Hove MC they were quite interested in the uniqueness of the car. Never say Never Eh!

Steve Swan

Well-Known Member

@Turbell . Your car will be a 4.7:1 final drive?? If you go late Dauph then you will have split case with 4.4:1 FD, but you can fit a std R8 CWP into this and have 4.1: FD. I dont think you can go any longer as the motor will not really have the torque to carry a bigger ratio. Got plenty R8 CWP in stock, so you just need the Dauph split case 330. I am afraid to ask, but how is the motor progressing ................

Steve Swan

Well-Known Member

Maybe a Supercharger?? Hat,coat etc.etc.etc

Turbell

Well-Known Member

Head off, liners protruding now crushed by about 0.05mm, new modern gasket, all built ready to go back in, when I can get it over there, it's in a corner sheeted up, fit it, run it dry at first to make sure it all starts up, then fill it and squeal off up the road with my phone switched off......@Turbell . Your car will be a 4.7:1 final drive?? If you go late Dauph then you will have split case with 4.4:1 FD, but you can fit a std R8 CWP into this and have 4.1: FD. I dont think you can go any longer as the motor will not really have the torque to carry a bigger ratio. Got plenty R8 CWP in stock, so you just need the Dauph split case 330. I am afraid to ask, but how is the motor progressing ................

Turbell

Well-Known Member

If I can be arsed I'll build another 670-5, got my eye on some cheap +1mm pistons, Metro turbo cam and a 28/36 DCD, leave current lump as a back up, can't see me buying anything new project car wise as prices are daft nowMaybe a Supercharger?? Hat,coat etc.etc.etc

Still want an A310, the one I nearly got my mitts on won't have progressed, it's in the back off my mind he'll fold at some time, and I can pounce like the true vulture I am......

I have enjoyed reading all your posts on the Dauphine it looks and sounds great its amazing how an old classic can be transformed although with considerable effort. I remember you and your wife competing in the Renault 8 at speed events. You had a quick one and a really quick one which I think had a Gordini engine both well prepared cars.

I think the last place I saw them was Forrestburn I was competing in a not so well prepared Mallock at the time. In recent years I moved on to single seaters although Covid restrictions have stopped all that. For something to keep me going in lock down times I purchased an old Lotus Europa S2 with the 1565cc Renault engine which I am currently restoring and my main reason for signing on to the forum. I look forward to seeing the Dauphine competing in the future no doubt it will be a competitive car in the class.

I think the last place I saw them was Forrestburn I was competing in a not so well prepared Mallock at the time. In recent years I moved on to single seaters although Covid restrictions have stopped all that. For something to keep me going in lock down times I purchased an old Lotus Europa S2 with the 1565cc Renault engine which I am currently restoring and my main reason for signing on to the forum. I look forward to seeing the Dauphine competing in the future no doubt it will be a competitive car in the class.

Steve Swan

Well-Known Member

Forrestburn in the late 90's What a time to be alive!! Did you normally have your son with you as chief helper? Remember most of the Mallock Guys Alex Graham, Kevin Tawse, Billy Macdonald, Iain Mitchell and yourself, there was also one double driven one guy was the old hills coordinator and his mate can't remember the names. Liz and I moved into circuit racing in the early 2000's and carried on up until about 2012, family pressures and having too many cars took its toll. Liz now has bad Arthritis in her hands, so her competitive driving days are over. I have kept my had in building transaxles for old Renaults, and last year have got involved in a R8GT turbo, which made me pull the Dauph out of hibernation. Junior is now 20, and passed his test 3 years ago, and there is a better than even money chance I will be back at Forrestburn if not in 2021 then 2022, so he can learn to drive and practice all the skills necessary in a non threatening enviroment, before going to the Circuits. Hills and Sprints, best racing school ever.I have enjoyed reading all your posts on the Dauphine it looks and sounds great its amazing how an old classic can be transformed although with considerable effort. I remember you and your wife competing in the Renault 8 at speed events. You had a quick one and a really quick one which I think had a Gordini engine both well prepared cars.

I think the last place I saw them was Forrestburn I was competing in a not so well prepared Mallock at the time. In recent years I moved on to single seaters although Covid restrictions have stopped all that. For something to keep me going in lock down times I purchased an old Lotus Europa S2 with the 1565cc Renault engine which I am currently restoring and my main reason for signing on to the forum. I look forward to seeing the Dauphine competing in the future no doubt it will be a competitive car in the class.

Thanks for your kind words and good luck with the S2 The Renault motor is much torquier than the ford could ever be.

DaveL485

Staff member

This needs it's own thread, pretty pleaseI purchased an old Lotus Europa S2 with the 1565cc Renault engine

Steve Swan

Well-Known Member

One of my last visits to Forrestburn hill with my better Half

Steve Swan

Well-Known Member

And finally while wallowing in nostalgia one of my better days at Knockhill. Got mugged into the first corner after a good start, and as one by one people fell off Ian Longford and myself find ourselves fighting for fourth. I knew that with the hairpin being real slippery courtesy of a blown up fiesta in the race before ours, if I could dummy him up the inside he would try too hard and maybe come unstuck

Sorry about the picture quality this was pre Go Pro

Sorry about the picture quality this was pre Go Pro

Yes Steve eldest son Martin was my helper he is now 36 I left the speed scene in 2001 following an engine blow up at Doune. Came back in 2015 I purchased a formula Vauxhall junior which myself and Martin entered in Scottish speed events. Three years ago I purchased an old F3 Dallara which we have had three good seasons in up to lockdown. Brought back memories watching your cars at Forrestburn on the video. The handling and traction of the Gordini engined one was always impressive the pressure got to the guy in the mark 1 at a wet knockhill as he lost it leaving the hairpin. Missed all the motor sport last season and I don't think much will happen this year . The lotus rebuild has kept me occupied I got the car last May the body work chassis suspension and inside are back together on the mechanical bits now

Steve Swan

Well-Known Member

Ok. Back to not making your Dauphine handle. I have been going round in circles with the reverse gear lockout for the Dauph. The gearbox is the most complex creation I have made thus far, and it shows promise. It naturally sits in the 3rd/4th plane but there is very little internal springing, so that when going for 1st/2nd it is easy to overshoot and end up in reverse gear territory. This means the reverse locker needs to provide a solid wall or gate for 1st/2nd then easily flip over to access reverse. I always try to stick to the K.I.S.S. principle. Keep it Simple Stupid, or in my case, Keep it Simple Steve (same thing really)

HOWEVER life just ain't like this, so here is how it ended up. Its primary redeeming feature is that it works well, but the hours I've burnt on this is crazy

Thanks for reading and Happy Motoring

Reverse locked out

Reverse unlocked. Incidentally the pedal box was another idea which seemed great at the time HO-HUM

HOWEVER life just ain't like this, so here is how it ended up. Its primary redeeming feature is that it works well, but the hours I've burnt on this is crazy

Thanks for reading and Happy Motoring

Reverse locked out

Reverse unlocked. Incidentally the pedal box was another idea which seemed great at the time HO-HUM

Steve Swan

Well-Known Member

I am on to the last 'big make' for the Dauph. Having a swing axle rear end is a bit of a mixed bag, it is not a disaster as it is better for traction than a live axle, has lower unsprung mass and does not alter wheel camber in roll, but the main issue is vertical camber change, or more accurately camber change due to vertical motion. Solution, Limit vertical movement. Well I wasn't taking it into the woods anyway. VW tuners and racers will know about camber compensators, these are another leaf spring mounted on a swinging bracket in the centre of the gearbox, and connected to each axle's outer end. This has no effect in roll as one goes up and the other down and pivots through the centre, but when the car rear compresses under acceleration or lifts under braking the extra spring comes into effect helping to limit the vertical travel. Problems with camber compensators is the centre pivot under the centre of the box loosing you ground clearance, no problem on standard ride height, but when you want it lower than a snake's ass in a wagon rut you have a problem. The super duper deluxe answer is to build a Zero roll resistance rear suspension, and a Guy called Ross in New Zealand did this, but was unhappy with the result and feel of the car. To make this means a redesign of the rear end, and to be honest I think I would have a real issue trying to get that through scrutineering as a historic vehicle, as it means connecting the top spring platforms to a triangular frame which pivots on the top of the gearbox. I personally think the problem with this is that you need some roll resistance on a saloon car as it has a highish centre of gravity. This could be accomplished by adding a 3rd spring and damper between the top of the triangle and the body meaning you having Mainsprings for vertical motion only (fairly high rate) and a roll control spring (low rate) and all 3 can be changed in 25lb/inch steps this would be lodsa fun to set up!!!!!!

I have elected for the 3rd option, based on a device fitted on '68 Beetles (period modification) and touched on in Fred Phun's excellent book 'How to make you car handle' This book is a must read for historic vehicle racers and modifiers, but out of date for Moderns

This is the Z bar which works in the opposite way from an anti-roll bar. The bar is straight, but mounted under the car on an angle with one link going forward to connect to the outer end of the axle at centre, and the other end has the link going back to the same spot on the other side. This means as the car rolls the bar pivots freely, but comes into play if the rear end tries to lift or squat. Last and most important point is that this device is fitted at Zero load when the car is on its wheels and with the rear springs compressed, meaning that it is more effective at stopping lift than preventing squat and is totally adjustable in this respect. Killing the lift under braking is the most important part.

The Mk1 version I used on the 8G used CDS tube as the bar with EN24t blades on each end which adjusted for stiffness by rotating, but the blades were quite short and were prone to snapping. When this happened in a race it was always the same. A loud Bang like a gunshot followed by the feeling that the rear tyres had melted in every braking zone. Proof positive that it was super effective at improving stability under braking and turn in. The MK2 version used Pug 106 (poverty spec) rear torsion bars, the only problem being that I had to spend an afternoon with the burning torch cutting up the rear axle to get the splined mounting points out.

Pic 1 shows the 106 bar with the splined mounts turned into tubes with the ends welded up and then welded in to solid driving links

Pic 2 shows the ends in more detail the mounts are high pressure pipe clamps bored to suit the torsion bar, cheap and easy, I use them for anti-roll bar mounts as well

Now I need to lie on freezing concrete to measure up the carrier frames from the Gearbox crossmember. A job for another day.................

I have elected for the 3rd option, based on a device fitted on '68 Beetles (period modification) and touched on in Fred Phun's excellent book 'How to make you car handle' This book is a must read for historic vehicle racers and modifiers, but out of date for Moderns

This is the Z bar which works in the opposite way from an anti-roll bar. The bar is straight, but mounted under the car on an angle with one link going forward to connect to the outer end of the axle at centre, and the other end has the link going back to the same spot on the other side. This means as the car rolls the bar pivots freely, but comes into play if the rear end tries to lift or squat. Last and most important point is that this device is fitted at Zero load when the car is on its wheels and with the rear springs compressed, meaning that it is more effective at stopping lift than preventing squat and is totally adjustable in this respect. Killing the lift under braking is the most important part.

The Mk1 version I used on the 8G used CDS tube as the bar with EN24t blades on each end which adjusted for stiffness by rotating, but the blades were quite short and were prone to snapping. When this happened in a race it was always the same. A loud Bang like a gunshot followed by the feeling that the rear tyres had melted in every braking zone. Proof positive that it was super effective at improving stability under braking and turn in. The MK2 version used Pug 106 (poverty spec) rear torsion bars, the only problem being that I had to spend an afternoon with the burning torch cutting up the rear axle to get the splined mounting points out.

Pic 1 shows the 106 bar with the splined mounts turned into tubes with the ends welded up and then welded in to solid driving links

Pic 2 shows the ends in more detail the mounts are high pressure pipe clamps bored to suit the torsion bar, cheap and easy, I use them for anti-roll bar mounts as well

Now I need to lie on freezing concrete to measure up the carrier frames from the Gearbox crossmember. A job for another day.................

Similar threads

- Replies

- 8

- Views

- 191

- Replies

- 3

- Views

- 93