a quick look online at a replacement clutch seem to have it listed as a 200mm clutch with a 26t spline center. Could do with confirming (@bloke can you help at all?) but thats the same as a gt turbo, 1.8 16v, williams and as such a volvo one too......hmmmmm could an uprated clutch be that easy? surely not.

There is more to life with TurboRenault.co.uk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Twingo Adey's Twingo GT (F4R+T 2.0ltr engine swap)

- Thread starter Adey

- Start date

Norwich Nick

Well-Known Member

From my research it is that easy

Good day down at the dyno shootout today, the dyno showed it having more hp than at efi but the same torque. ill trust efi's rollers i think. It surprised them down there when i told them it was a little 1.1 turbo engine that came factory turbo charged rather than something i built. Had a little play with a 182 afterwards too and tbh there next to nowt in it! It would probably spank me above 100 but up till then its all good fun  pic from @Spooky

pic from @Spooky

Great power increase for a small cc engine with bolt on mods.

not bad really, could prob gain a little more pushing it harder lower in the revs but it was mapped safe as its an unknown. still quite rich and stuff.

Turbo gasket kit has been ordered, so ill be able to see if the bigger turbo i have will go on soon hopefully. My understanding is the torque lower down in the revs (where most bend things?) will be less and move the whole power band upwards, hopefully the engine will want to rev some more. To be fair currently we could of held the revs a few 100 rpm higher but only moved it 100 up on stock to stop me hitting the limiter all the time

D

Deleted member 486

My understanding is the torque lower down in the revs (where most bend things?)

Personally - I believe that this is a myth although there is an explanation. In reality, torque is torque is cylinder pressure regardless of where it happens in the rev range. If the engine is producing peak torque it will be working at peak cylinder pressure too. It's just very easy with a (stock / small) turbo to increase the bottom end torque beyond the limits of the engine whereas the top end other factors come in to play (choke line, compressor temps etc.).

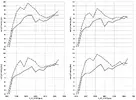

For exhibit A have a look at the pictures below - this was done on an engine dyno with a 1.5 turbo 4 pot (solid line is standard, dashed line is mapped - second set of graphs are cylinder pressure averaged over 300 cycles for which the limit on this engine was 100 bar). All stock components and keeping within the design limits of the engine.

It was the cylinder pressure limit at the bottom end that held me back (not turbo or anything else as I was operating at <75% wastegate duty below 3,500rpm) so I could have pushed harder which would have increased the cylinder pressure beyond the capability of the engine. It was only from 5,000rpm onwards that I had the wastegate closed as the cylinder pressure allowed me to run it flat out. A tuner doesn't have access to the design limits or the equipment to measure this (the pressure transducers alone are something like £2k per cylinder, and you'll need a new set depending on plug heat range / thread etc., let alone all the rest of the logging equipment) so they effectively go on gut feel. Unless you're stupid the parts won't fail instantly but the additional stress eats away at the "fatigue life" of a component so it just wears out more quickly. For a lot of the time people will drive a mapped car in the bottom end of the rev range, using the increased torque, which is why engines will fail in this region.

The biggest issue, for me, with creating lots of power down low is that the water pump will not be able to deliver adequate cooling as it will be spinning slowly and so the flow will be low whereas the engine is trying to reject a lot of heat (especially in the cylinder head) - again, another reason engines could fail at low speed.

Gearboxes generally don't like lots of low down torque (especially from low cylinder count engines) because of the huge torque spikes that occur at each firing event. The more torque the bigger spikes - and the further apart they are in lower cylinder count engines the bigger the difference between the peaks & troughs of waiting for the cylinders to fire.

Having said all that - I bet that car is an absolute riot to drive now!

Personally - I believe that this is a myth although there is an explanation. In reality, torque is torque is cylinder pressure regardless of where it happens in the rev range. If the engine is producing peak torque it will be working at peak cylinder pressure too. It's just very easy with a (stock / small) turbo to increase the bottom end torque beyond the limits of the engine whereas the top end other factors come in to play (choke line, compressor temps etc.).

For exhibit A have a look at the pictures below - this was done on an engine dyno with a 1.5 turbo 4 pot (solid line is standard, dashed line is mapped - second set of graphs are cylinder pressure averaged over 300 cycles for which the limit on this engine was 100 bar). All stock components and keeping within the design limits of the engine.

It was the cylinder pressure limit at the bottom end that held me back (not turbo or anything else as I was operating at <75% wastegate duty below 3,500rpm) so I could have pushed harder which would have increased the cylinder pressure beyond the capability of the engine. It was only from 5,000rpm onwards that I had the wastegate closed as the cylinder pressure allowed me to run it flat out. A tuner doesn't have access to the design limits or the equipment to measure this (the pressure transducers alone are something like £2k per cylinder, and you'll need a new set depending on plug heat range / thread etc., let alone all the rest of the logging equipment) so they effectively go on gut feel. Unless you're stupid the parts won't fail instantly but the additional stress eats away at the "fatigue life" of a component so it just wears out more quickly. For a lot of the time people will drive a mapped car in the bottom end of the rev range, using the increased torque, which is why engines will fail in this region.

The biggest issue, for me, with creating lots of power down low is that the water pump will not be able to deliver adequate cooling as it will be spinning slowly and so the flow will be low whereas the engine is trying to reject a lot of heat (especially in the cylinder head) - again, another reason engines could fail at low speed.

Gearboxes generally don't like lots of low down torque (especially from low cylinder count engines) because of the huge torque spikes that occur at each firing event. The more torque the bigger spikes - and the further apart they are in lower cylinder count engines the bigger the difference between the peaks & troughs of waiting for the cylinders to fire.

View attachment 138290

View attachment 138291

Having said all that - I bet that car is an absolute riot to drive now!

Some good stuff there but it depends on the way that the torque is requested. I agree that torque is torque but there will be a higher cylinder pressures based on what load is requested if you just plant your foot rather than a gentle ramp increase. The megs bent rods on the 774 f4r engine at varying levels , some were just above idle - I know of a car at 1800rpm that threw a leg and others were cruising at 70 on the motorway. It was rare to see them fail when revving out.

Now they are doing ringlands due to a weak fuel in cylinder 4.

D

Deleted member 486

Some good stuff there but it depends on the way that the torque is requested. I agree that torque is torque but there will be a higher cylinder pressures based on what load is requested if you just plant your foot rather than a gentle ramp increase. The megs bent rods on the 774 f4r engine at varying levels , some were just above idle - I know of a car at 1800rpm that threw a leg and others were cruising at 70 on the motorway. It was rare to see them fail when revving out.

Now they are doing ringlands due to a weak fuel in cylinder 4.

The cylinder pressure is the same regardless of how the torque is requested - it's the pressure that gives you the torque. If there's slightly poor boost control and you get overboost on a tip-in then that will obviously not be good and could lead to sudden spikes in cylinder pressure. And as I say, a bit of over-pressure generally doesn't hurt engines instantly (at Ford we ran a standard turbo 4 engine in to knock at over 300 bar cylinder pressure with no instant damage to rods or cranks), it's going there a lot that does the damage.

My guess would be it was something else causing the failures rather than boost - sounds more like something gets hot and seizes than boost related unless they've had a lot of abuse.

Revving out, the turbo won't be able to supply the air to over-pressure the cylinders so it'll be unlikely to fail up there.

Just as another little touch, this car is still doing its mpg thing. I filled up 5 miles from EFI, did 5 hours there with plenty of full bore pulls, A brisk 3 hour run home afterward, Fridays work commute, another dyno day in Gloucester along with some "playing" whilst over that way, the Monday commute and then the fuel light came on. Filled back up and worked out the usage at 39.85mpg. Not bad at all considering the fun, scoff did say when cruising mpg should stay near identical as it was and i think this prove that nicely. Shouldnt take much self control to nudge it back up to near 50mpg again (i had 54ish when running around on no boost for 2 weeks)

D

Deleted member 486

It is normally the BMEP pressure inside the cylinder that causes the meg engines to fold. Thats sadly been proven

BMEP is literally just specific torque output used to compare engine output of different sizes. If tuners / engine builders are quoting this as directly comparable to cylinder pressure then they're talking out of their posterior - the graphs above have an identical (as near as dammit) BMEP from 2,200 to 3,750 (as the torque is the same) but you can see that the cylinder pressure varies quite a bit over that range. A big BMEP just means that you have a high torque for that capacity.

I have no doubt that it comes down to cylinder pressure that makes the Meg engines fail but they will be failing due to fatigue rather than an instant pressure spike - although that instant pressure spike will be the instantaneous cause of the engine failure.

The only way to truly safely map an engine is to run it with about £20k of instrumentation and the design specification of the components to make sure that you don't exceed them. The issue is that no-one knows how close to the design limit an engine runs apart from the people who made it so it's all guesswork. Increasing performance will just decrease the overall life of the component.

Similar threads

- Replies

- 3

- Views

- 346

- Question

- Replies

- 0

- Views

- 200

- Replies

- 35

- Views

- 2K