There is more to life with TurboRenault.co.uk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How (not) to make your Dauphine Handle

- Thread starter Steve Swan

- Start date

Steve Swan

Well-Known Member

@Brigsy ,thanks for that. One of the biggest problems of these old Rear engined Renaults is that the standard geometry is a bit weird in an attempt to make them safer in general use. You need to make quite a lot of changes to get what you want. There is no substitute for actually measuring your car, any car, as I have done a few over the years from saloons to single seaters and have never found one that did not have correctable errors. Also every change you make e.g. Lowering or adding castor (popular on FWD cars) will always knock the steering out a bit, and it is not usually that hard to fix. I have always found that the improvement in feel and feedback from the chassis is worth the effort in the end

Absolutely mind blowing thread @Steve Swan !

Great to see the little adjustments you make and their impact on the measurements.

Great to see the little adjustments you make and their impact on the measurements.

Mark_L

Well-Known Member

I can't help it, it's my age. When I go into small numbers esp. sub 1mm, I go into thou its easier to visualise. I try to stay in mm as most people prefer that and can visualise it. Going sub 1mm its all bits of things, like 0.1mm=4 thou=1 Rizzla Green (other cigarette papers are available)

All pert of the fun

I mix them all the time. I work in old school myself but sometimes mix them for ease..

Steve Swan

Well-Known Member

Steve Swan

Well-Known Member

Actually, thinking about the Image wheel it would make a cool MK1 5 wheel as the rotor pattern would not have to be changed for the small 3 stud PCD

Steve Swan

Well-Known Member

Been back in the machine shop this week. I always seem to end up with 3-4 things on the go instead of 1, So I'm still finishing off the gear locker on the Dauph and Fabricating all the bracketry for the Z bar for it. Then I get a call telling me I'm getting a couple of gearboxes delivered, an early R8/5G Hybrid i built a few years back plus what looks like a R16 5 speed minus its crownwheel and pinion shaft . First job was to strip the 16 box of its useful bits and bin the rest, then check over the Hybrid, it has picked up a bit of damage on the endcase so it was removed and I have started to modify a couple that have been lying around, also the Modified universal joints are the original MK1 type which needed upgrading to MK2 which makes them oiltight and as the welding gear was set up I welded up the bits of Z bar brackets that were ready . Chaos as usual

C1J followers have their uses

Welded end cap stops oil leaks

R8 box With R5G transplant

Making lots of swarf chopping R5G case

Z bar droppers

I'm Rusty, that's my excuse and I'm sticking to it.

C1J followers have their uses

Welded end cap stops oil leaks

R8 box With R5G transplant

Making lots of swarf chopping R5G case

Z bar droppers

I'm Rusty, that's my excuse and I'm sticking to it.

Steve Swan

Well-Known Member

@Adey . The biggest problem is finding the parts. Your Dauph would work well with a Big 4 speed, Which you could probably build yourself you would need to find a set of R8/10 casings Mid production type (anything with a 20 spline input shaft ) the ones you have in your car are early production and have no pinion bearing location ring (which is alright in that box, but does not lend itself to further modification) Then you need to find a R 16 box (4 speed) Then the biggest problem is finding a gearcutter to respline the U/J inners to R16 spec. I had a firm, but they closed down and I had not realised, otherwise I would have tried to buy the tooling from them. I have the spec and sizes, but I need to find or have a hob tool made, and the cost is prohibitive. If I had this then any gearcutter could do the job for me. There has not been enough demand of late to warrant the cost. Any suggestions gratefully recieved. Just for fun there is a French company who can make you a 364 (monte type) trans for 10K and there is supposed to be someone in Hungary doing 353 R8G type transaxles for 5-8K. This makes my prices seem very cheap, but the drawback is finding the bits to do the conversion. The other issue it is easy to forget is that you must not overgear these old cars, I have been reading through your Twingo thread and consider it an education! The thing is it produces a lot of torque for what it is and will pull long gears, perhaps not very well, but it will do it, which is why you want to lengthen 5th for Motorway work. If you keep the old car an atmo then a good 1400 will give you 100-110lbs/ft and that's it. I'm hoping that my 1700 might crack 140lbs/ft ok it will be at 6000 rpm and will rev to 8000, so will have knocking on for 200 bhp, but it won't be a relaxing drive on the road. I get lots of enquiries from people with older cars and ultimately they want something with the legs of their current roadcar, which is just not possible as yesterdays engines cannot produce the torque of modern diesels and the new Petrol turbos. For what its worth you can mate the K4M block to the R8 bellhousing if you fancy a big challenge for yourself (a ballistic parachute would be optional for emergency stops) I have never really looked into this as I am always on thin ice for originality/period for competition, so would be banned from doing this. You could build the ultimate Dauphine, a drive it to the Ring, and kick its head, and drive it home car. It may be a monumental enough task to keep even you busy for a couple of years, Esp. if you made it transverse engine in the back....................... less weight overhang............. lower polar moment................. I think I will leave it there.

DaveL485

Staff member

...get flown home in an air ambulance.a drive it to the Ring, and kick its head, and...

Steve Swan

Well-Known Member

Is this a Bitter memory or wishful thinking,I can't seem to make my mind up....get flown home in an air ambulance.

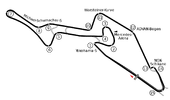

Only been to the Ring once in 2008. We did the ADAC 400k Eiffelrennen 8 laps of the Complete North loop and the GP circuit. We used my mate Ian's RS2000 4 laps each and change at half distance on the Saturday and the second half on the Sunday. Needless to say we were unprepared for Endurance racing and lots of things worked loose (this was common to many competitors that weekend) WE were paddocked on the Mercedes Arena part of the GP circuit as we used the shortcut chicane and the pictures show where we swapped out the engine and box on the Friday due to Failure in practice. What a blast though! The highlight of my Motorsport career............. so far????????

The following picture was taken right at Position 2

Yours truly Really there is nothing to smile about !

Steve Swan

Well-Known Member

Steve Swan

Well-Known Member

Got a new toy for Chrimbo a 3D printer

Good fun, but lots to learn

Very clever how it builds a honeycomb inside the item. Super light and very strong for what it is

Been busy printing some plug wire seperators and a couple of rollcage hooks for the wheel and my crash hat

More distractions to follow

Thanks for watching

Good fun, but lots to learn

Very clever how it builds a honeycomb inside the item. Super light and very strong for what it is

Been busy printing some plug wire seperators and a couple of rollcage hooks for the wheel and my crash hat

More distractions to follow

Thanks for watching

Steve Swan

Well-Known Member

@Adey . You don't need to know about drawing programs, unless you want to design from scratch. There are literally thousands of projects out there you can simply download and print. The rollbar hook was designed to fit a 45mm tube??? I simply re-scaled it down 14% to make it fit my 38mm A hoop , worked perfect. Lots of stuff is just fun and nonsense, but for instance have managed to find a snap in wheel centre at 60mm which I should be able to re-scale to fit my Deltamic copies, much less hassle than turning it up in aluminium then having to invent a fitting mechanism. It is a bit like the lathe and the mill, once you have them, you start to find work for them, I should really retrofit 2 axis CNC to the mill, it would make it much more versatile.

Turbell

Well-Known Member

Witchcraft, I tell you.

Either that or they'll start auto printing little Chinese robot killing machines at night and take over the world, and we'll have to rise up against them and shoot them with proper homemade longbows and swords 'n' stuff like that.

I'm looking forward to it.

Either that or they'll start auto printing little Chinese robot killing machines at night and take over the world, and we'll have to rise up against them and shoot them with proper homemade longbows and swords 'n' stuff like that.

I'm looking forward to it.

Steve Swan

Well-Known Member

Finally managed to drag myself to the workshop today to progress the 5 speed hybrid that has come back to me before going to its new home. Replaced the 5th gear housing end, and buttoned it all back up, just need to tidy up the linkage and open the diff carriers to check that there is no issues with the diff bearings and it is ready to go to it's new home

If you own a mk1 5 Gordini, Alpine or Turbo, and the gearstick seems loose, and you have sorted out the linkage bushes, pound to a penny these bronze bushes are worn and need replacing

So that's the end all buttoned up. Just needs the linkage tidied, then check the diff bearings

Happy new year

If you own a mk1 5 Gordini, Alpine or Turbo, and the gearstick seems loose, and you have sorted out the linkage bushes, pound to a penny these bronze bushes are worn and need replacing

So that's the end all buttoned up. Just needs the linkage tidied, then check the diff bearings

Happy new year

Very pretty Steve!Finally managed to drag myself to the workshop today to progress the 5 speed hybrid that has come back to me before going to its new home. Replaced the 5th gear housing end, and buttoned it all back up, just need to tidy up the linkage and open the diff carriers to check that there is no issues with the diff bearings and it is ready to go to it's new home

View attachment 152509

If you own a mk1 5 Gordini, Alpine or Turbo, and the gearstick seems loose, and you have sorted out the linkage bushes, pound to a penny these bronze bushes are worn and need replacing

View attachment 152510

So that's the end all buttoned up. Just needs the linkage tidied, then check the diff bearings

Happy new year

Steve Swan

Well-Known Member

Been hibernating up here recently. Was scraping the car windows before going for the shopping yesterday at 8.30 and the temp gauge was saying minus 7 ! Wondered where my fingers went.

Have been reading up on others threads and was looking in at @Adey for his proposed transplant and was looking at his gear ratio options. Rather than clog his thread up with rubbish I thought I would post the Dauph's numbers here. They are not ideal, but the best compromise that can be worked out from production parts on 300 series based boxes.

I have set the shift point at 7500rpm as a median as you would use 5500 on the road and the full 8000 in the first 3 gears on the track (dependant on circumstances wet or dry how many metres to the next brake point)

Axle ratio is 9x34 3.77:1 1st is 3.41:1 2nd is 2.25:1 3rd is 1.61:1 4th is 1.21:1 and 5th is 0.97:1

Have been reading up on others threads and was looking in at @Adey for his proposed transplant and was looking at his gear ratio options. Rather than clog his thread up with rubbish I thought I would post the Dauph's numbers here. They are not ideal, but the best compromise that can be worked out from production parts on 300 series based boxes.

I have set the shift point at 7500rpm as a median as you would use 5500 on the road and the full 8000 in the first 3 gears on the track (dependant on circumstances wet or dry how many metres to the next brake point)

Axle ratio is 9x34 3.77:1 1st is 3.41:1 2nd is 2.25:1 3rd is 1.61:1 4th is 1.21:1 and 5th is 0.97:1

Last edited:

Similar threads

- Replies

- 8

- Views

- 191

- Replies

- 3

- Views

- 93