r5gordini

Well-Known Member

Exciting update time!

I started wiring up the ECU.

Taking it slowly, I wired in:

Yaaay! I can read the sensors... Except - the coolant temperature is very low?

It turns out that there are internal bias resistors for the sensors, so I had to play with the calibration settings a bit to get this:

I may play a bit more, but at least it's now working! I tweaked the settings so that the air intake temp and coolant temp are equal and they have tracked pretty well so far, but only over a few degrees as I struggle to heat my garage over 12 C and it's not dropping very much overnight.

TPS is also showing nicely 0-100%.

I then wired in the TDC sensor and connected up the main battery wire and checked the tooth pattern:

To my untrained eye that looks pretty good!

I then wired in the Zeitronix:

Hmmm... It's all looking a bit messy now! I've added a couple of inline fuse holders and the extra wires are getting in the way. I'll try and tidy it up with some cable ties, but right now it's just a case of getting things working.

The Zeitronix unit seems to be working - it's sending data but I can't test properly until I have the engine running.

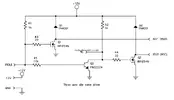

Next I need to wire up the fuel pump relay from the ECU (lack of proper/safe fuel pump control from the old ECU is one of the main reasons for the switch to Megasquirt) and then the coils and injectors. I'm still going to need to construct a circuit to control the logic-level coils. I have ordered the TC4427 from RS. They should arrive today.

I have started wiring in the relay for the coils and injectors. The high current feed from the battery has a connection point inside the rear o/s of the engine bay and connects to the starter and alternator from there. I'll take a feed from it, fused, to the relay, which will be placed close to the coils and will be triggered from the fuel pump relay. This is my solution for providing high current for the coils and injectors in one!

I started wiring up the ECU.

Taking it slowly, I wired in:

- Power from ECU relay

- Ground (x4!)

- TPS

- Coolant temperature

- Air temperature

Yaaay! I can read the sensors... Except - the coolant temperature is very low?

It turns out that there are internal bias resistors for the sensors, so I had to play with the calibration settings a bit to get this:

I may play a bit more, but at least it's now working! I tweaked the settings so that the air intake temp and coolant temp are equal and they have tracked pretty well so far, but only over a few degrees as I struggle to heat my garage over 12 C and it's not dropping very much overnight.

TPS is also showing nicely 0-100%.

I then wired in the TDC sensor and connected up the main battery wire and checked the tooth pattern:

To my untrained eye that looks pretty good!

I then wired in the Zeitronix:

Hmmm... It's all looking a bit messy now! I've added a couple of inline fuse holders and the extra wires are getting in the way. I'll try and tidy it up with some cable ties, but right now it's just a case of getting things working.

The Zeitronix unit seems to be working - it's sending data but I can't test properly until I have the engine running.

Next I need to wire up the fuel pump relay from the ECU (lack of proper/safe fuel pump control from the old ECU is one of the main reasons for the switch to Megasquirt) and then the coils and injectors. I'm still going to need to construct a circuit to control the logic-level coils. I have ordered the TC4427 from RS. They should arrive today.

I have started wiring in the relay for the coils and injectors. The high current feed from the battery has a connection point inside the rear o/s of the engine bay and connects to the starter and alternator from there. I'll take a feed from it, fused, to the relay, which will be placed close to the coils and will be triggered from the fuel pump relay. This is my solution for providing high current for the coils and injectors in one!