DaveL485

Staff member

HT leads cleaned and attached

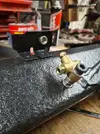

New fuel lines fitted from the hard pipes to the reg/rail

And there's that little woggle for the TDC sensor wire

Cleaned, painted and fitted the power steering pump rear support, this is also an earth point and the bottom bolt holds the oil level sensor bracket too, which was also all fitted.

Inlet manifold support cleaned, painted and fitted

After so long sat doing nothing it seemed surprised to be back in use!

New fuel lines fitted from the hard pipes to the reg/rail

And there's that little woggle for the TDC sensor wire

Cleaned, painted and fitted the power steering pump rear support, this is also an earth point and the bottom bolt holds the oil level sensor bracket too, which was also all fitted.

Inlet manifold support cleaned, painted and fitted

After so long sat doing nothing it seemed surprised to be back in use!