Little update:

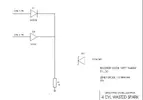

Yesterday I untaped the loom I made for the revcounter, double checked the diodes. All are correct.

I even tried wiring it onto the other coil wires, just incase it was on the wrong pair. Tried all combinations and still nothing.

I literally have a dead rev counter unless it's wired onto one of two of the coil -ive signal wires.

Still have 50% read. Not really sure where else to go, other than to butcher my cluster and intergrate a universal rev counter into it somehow. One that is adjustable and can be set up with the pulse rate I currently have. Which is 1 pulse per 2 revs. (I think)

Today was exhaust fitting day.

Nice 40 odd mile drive to Bromley this morning.

Up in the air, old shit stripped off, and mocking up the new harware:

The guy did a really good job of keeping it close to the manifold. It's given me an extra 5mm or so of room between DP and brake MC.

He's also fitted a bolt on flange just above the drive shaft, for ease of removal when I drop the engine out later this year. Means I can leave the DP fitted to the turbo as it's an utter SWINE to do the 3 nuts up.

Nice and central in the tunnel, with underfloor sports cat, and flexi fitted.

He's also fitted anaditional mount on the cat to the body.

Only thing I forgot to do was tell him the post cat lambda is tucked down the back of the engine bay. So on my next visit when they do me a 2.5" middle and rear box, I'll get him to weld a boss in for me.

And the top end. We have some distortion on the turbo flange though, and the genuine gasket isnt sealing it up quite well enough.

When it comes apart later this year, I've got some shorter studs to fit, so can get rid of the dodgey nut spacers hes used, and a fatter gasket to try to fill the gap up a bit better.

It's literally blowing the tiniest little bit though. Cant hear it any more when driivng the car like I could.

Getting a nicer power delivery off the line for sure. No more juddery running when cold either.

I've developed a bit of a breating issue with the gearbox too. It's pumping oil out of the top breather.

Gonna dump the oil out at the weekend, and re-fill with some proper stuff, as I'm not sure if the old 5/30 ive chucked in there is foaming or something silly like that.