Hi,

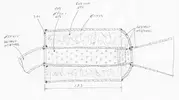

I have started to dissect the old devil exhaust I have. The inner perforated tube was broken and most of the steel wool filling had burnt out.

Last year, I had already made a jig to ensure that I would be able to reassemble it. Just last week I received two pieces of perforated tube and a box of steel wool (both stainless steel).

Yesterday I have cut the exhaust apart and discarded the old perforated tube and the leftovers of the wool. The front cap is not in very good shape, so I think I shall replace it with a flat plate. This means that I shall also need a slightly longer outer pipe. I hope to get those after Easter. In the meantime I also want to have the end re-chromed.

To be continued.

Cheers,

Erik

I have started to dissect the old devil exhaust I have. The inner perforated tube was broken and most of the steel wool filling had burnt out.

Last year, I had already made a jig to ensure that I would be able to reassemble it. Just last week I received two pieces of perforated tube and a box of steel wool (both stainless steel).

Yesterday I have cut the exhaust apart and discarded the old perforated tube and the leftovers of the wool. The front cap is not in very good shape, so I think I shall replace it with a flat plate. This means that I shall also need a slightly longer outer pipe. I hope to get those after Easter. In the meantime I also want to have the end re-chromed.

To be continued.

Cheers,

Erik