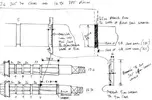

The group A boxes when compared to group B are inferior when examined like for like; for example the gears are narrower, synchro hub tapers are different, detent balls are 8mm compared to 10mm but most importantly the sunwheels are small in diameter and narrow 11.8mm (see drawing A)

The group B boxes have the larger improved size sunwheels 13.3mm, wider gears, better synchro design(R16), 10mm detent balls and the guided ball bellhousing casting to name a few. (see drawing

. Incidentally the 4 and 5 speed 8 Gordini boxes all hail from the group A design and have early sizes ,but the differential has been uprated by adding another pair of planet gears (4) and this therefore reduces the loading on the narrow design teeth by doubling the number engaged. To achieve this requires 2 extra cross pins which themselves require 2 extra roll pins to retain them . These pins can and do come out of their locations and can wreck a transmission

As a footnote to all this Mr Wheeler has found out that very late production 5 speed boxes have a strenghthened crownwheel and pinion we suspect this is as a result of renault revising their gearbox final drives around 1969 as any R 16 manual will show

The group C boxes have the drain plugs in a different location under the diff and are some 25mm approx longer measured from axle to bellhousing gasket face . This is due to its very large crownwheel size. These boxes utilize the large sunwheelas in drawing C and are the strongest production items available. Many other areas of the box are uprated and the true Monte-Carlo box has even stronger gear teeth.

WHAT COMPONENTS ARE INTERCHANGEABLE WITHIN GROUPS ?

Group A bellhousings can be upgraded to group B by directly swapping the items ,but the clutch input shaft also has to be exchanged as the oil seal position is different

The group A differentials can be directly swapped for the later group B type as an insurance to reduce the problems with weak sunwheel teeth. For example an R8 G 330 4-speed with a sheared sunwheel could be repaired by fitting the group B diff carrier complete or conversley a weak type replacement sunwheel could be fitted

The principle bearings are common to all ie; diff side bearings,but beware the internal bore differs in diameter one side to another. Pinion bearings can be replaced with care and have to be located with Loctite or similar industrial adhesive, however these tend to last the lifetime of the box

UNIVERSAL JOINTS

These can be grouped like the transaxles as follows:

Group 1: 1962-1972 from 956 R8 to 1300 R10 inc caravelle Alpine and Gordini models. This joint is standard and represents the most common and weakest and has a large rubber central bump stop located in a hole drilled in the Hardy Spicer centre. This hole seriously weakens the joint and failure is instant , with the cruciform breaking into 4 pieces. Wear rates are quite good due to its large needle bearing surfaces and dust/water free operating enviroment

Group 2: Renault offered a 'competition' UJ to suit the above models which simply did not have the drilled hole formed and hence is solid centered and resists fracture much better (these are now no longer available but Steve Swan can convert your standard ones with solid centres contact the home page for details)

Group 3: As group 2 solid centered but the inboard yokes are resplined to 23 spline x 25mm diameter to suit the bigger sunwheels found in the 364 box these are not available from Renault but we have had A batch made and may look at doing more if there is enough interest

Group 4: As group 3 but has big splines inboard and outboard for use with 'Big' Halfshafts something neither Mr Wheeler or Mr Swan has found neccesary ----------------------Yet!!

When U/J failure takes place, it is usually in association with sunwheel shearing. Due to the compact nature of the swing axle and its carrier, the flailing U/J yokes can jam against the tube. Loss of drive is then apparent, however if the U/J has only broken it is possible to gently move the car under power. ( or even qualify if you don't mind your vision going blurry at 100mph with the vibration) A note of caution must be made here, if you intend towing a car in this condition any distance suspended towing is recommended as the broken joint is now 'running' inside and against the axle tube. Considerable scoring and weakening of the tube can occur.

The standard joints are, in Renaults words, sealed for life and unrepairable. We repair the joints by substituting standard universal joints part no PUJ2211 (24 x 63.4mm) available from any bearing suppliers which are solid centred and uprate the joint to group B spec as well. These joints are designed to be circlip located and not staked as the originals were, so this involves machining grooves in the yokes for the circlips ,but then makes the joints serviceable as centres have to be replaced periodically when racing. I regularly check the backlash on the rear wheels and if it is excessive then I replace the centres. I have become quite good at spotting a U/J that has broken needles.

WHAT COMPONENTS FROM NEWER F.W.D. MODELS CAN

I FIT TO MY GEARBOX TO UPRATE IT ?

The fundamental differences between R12, R16,R18 and fuego 3xx type boxes when compared to the R8/R10 box is the omission of the 6 long M10 studs to each side case which allows the swing axle to be fitted. Ignoring the end casing differences what you have left is very similar to the 330 box contents, but the differential is considerably beefed up and uses large sunwheels(as sketch D ) which are slightly larger in diameter than the strong 364 box type

The main gear trains, gears, synchros, selectors, reverse idler and bearings are all very similar to the late type 330 boxes. it is only when we examine the later 2 liter and above engined cars that the components grow significantly in size. so we find that a large range of FWD models exist which under the current circumstances can provide a source of parts for swapping with RWD boxes. These vehicles can be sub-divided again by the way the crownwheel and pinion are installed in the casings i.e. an R8 crownwheel is located in the L/H side half case of the boxwhen viewed from the bellhousing , so is the R16 TL, TS, TX & R5 Alpine/Gordini, but the R12,R18and fuego are located in the R/H case And if fitted would give 1 forward and 4 reverse gears!

We use the good old R16 as a donor ; TL or TS for a 4 speed and TX for 5 speed. These complete drive trains/ diff etc can be persuaded to fit R8/10 casings withsome minor modifications to the casing to clear the larger crownwheel. The diff carrier is some 11mm wider than the original, which requires a suitable spacer between the casing and swing axle carrier to compensate for this.

The conversions are all slightly different in their details. The 4 speed uses all the gears and forks from the R16 box, but uses the R8/10 rods as the R8 endplate and shift mech are unchanged. The 5 speed conversion uses all the 5 speed parts and only the original sidecasings are used so these can be the early type with the detents opeded up to suit the later size parts. This means cutting a bigger clearance hole under the rear seat squab, but gives you a 5 speed box for your R8 without the need for any R8 5speed parts, you will of course have to make your own linkage, but this is not too complicated to do.

There were a few special tuning parts available for R8 boxes ' Mountain' Ratio kits and the 'mille tour' (1000 rpm drop) ratios these are quite rare and hard to come by so are outwith the reach. of most people, however there is an alternative

The Renault 365 gearbox was a close ratio box fitted to Alpine A310, R 12Gordini and R17 gordini. The best of these was the late mk1 17G box of types 365 33 and 34. These have the closest ratio's of any production Renault box and the synchro arrangement of 3rd and 4th gear is as mechanically strong as a light commercial vehicle. With a little modification these ratios can be fitted onto a R16 TX pinion shaft, which gives you a close ratio 5 speed box for your R8.

It is also possible, as I have just found out, to cut and shut a 4speed and 5 speed shaft to give the 4 speed final drive ratio on a 5 speed box, this is the most complicated of all the conversions and it is this conversion I will try to explain piece by piece on the next few pages.

The sunwheels (type D) are then shortened to R8 length to fit the universal joint. The result is a 364 style transaxle at a fraction of the cost of the genuine article. If you go down the route of the close ratio gears you actually have a very superior transaxle to anything produced by the Regie.

The next link in the transmission train are the universal joints, standard R8/10 ones will require boring out and resplining to suit the large sunwheels, or if you can find some 364 joints as in group C then fit straight on.