Neal R19

Well-Known Member

Alright chaps, been doing some thinking about the fuelling on my Turbo Shed.

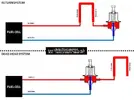

Since I'm running a mk2 225 engine/fuel rail and planning to run it on the OE ECU (at least to begin with) I need to match the 3.5bar static fuel pressure from the standard in tank sender. Non return system.

The sender wont fit in the 19's tank, so here's what I'm thinking of doing:

- Fit a walbro GSS342 (or HRC equivalent - anyone got any 1st hand experience of these?) into the standard 19 sender unit in the tank (which has feed & return)

- At the outlet of the sender, pass it to a pre-set 3.5bar reg, which sends fuel back to the return stub of the sender. Like this one:

- T piece into the line between the pump and the reg and send that off to the fuel rail.

Any reason why this is a dumb idea?

I can just leave the vacuum reference port on the reg alone and it will just sit at 3.5bar exactly as the standard one does?

Since I'm running a mk2 225 engine/fuel rail and planning to run it on the OE ECU (at least to begin with) I need to match the 3.5bar static fuel pressure from the standard in tank sender. Non return system.

The sender wont fit in the 19's tank, so here's what I'm thinking of doing:

- Fit a walbro GSS342 (or HRC equivalent - anyone got any 1st hand experience of these?) into the standard 19 sender unit in the tank (which has feed & return)

- At the outlet of the sender, pass it to a pre-set 3.5bar reg, which sends fuel back to the return stub of the sender. Like this one:

- T piece into the line between the pump and the reg and send that off to the fuel rail.

Any reason why this is a dumb idea?

I can just leave the vacuum reference port on the reg alone and it will just sit at 3.5bar exactly as the standard one does?

Last edited: