Alright alright!

So recently I've dropped the engine out again as I need to fit a brake hydraulic system.

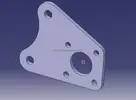

A reminder of the clearance between the master cylinder and the downpipe:

Not very much! That's actually the scenic RX4 M/C fitted which I was thinking of using, but it only has 2 ports as I guess the ABS on that vehicle sorts out the split circuit and force distribution etc. Issue is the ports are exiting the wrong direction. The original 19 one has all 4 ports and of course no ABS. Each port straight to a caliper.

So anyway What I needed was a M/C with 2 ports, pointed away from the downpipe instead of towards it. Pug 406 V6 one fits the requirements. 23.8mm diameter, so slightly bigger than the 23mm one that the scenic uses. Should be OK.

I lopped off the unused casting stubs where ports would be on another variant to give me a bit more clearance.

Then just mounted it and made up some lines. Becasue I have no ABS to sort out the split etc, each port goes to a T piece mounted on each inner wing. From there it obviously branches to one front and the opposite rear caliper. I hate making brake pipes!

Yeah, so there's a bit of a corrosion issue there.

I chopped loads of it out and welded on a new plate:

No photos of the finished job as to be perfectly honest I'm ashamed of it. It should be strong at least, and I covered my tracks by slathering round it with seam sealer and spraying with underseal :bf:

Then I figured my brake setup would need a decent amount of heatshielding so as not to get cooked by the downpipe. Luckily I picked up a couple of bits of that nimbus type stuff from the verge of the motorway roundabout near where I live recently that obviously fell off a car. Looks like they came off a Ford.

So chopped em up and made a little double layered shield that bolts to the chassis rail.

Then started butchering the original meg225 bulkhead heatshield to fit next to it.

Yeah, reckon that will work alright. Now need to make some more shielding for the gearshift box and cables...