Neal R19

Well-Known Member

Converting from cable clutch to hydraulic clutch

Getting to a workable solution for this took a lot more time and effort than it had any right to.

Three options:

A - Fit all the pedals from the Megane - including the brake transfer bar, relocating the servo and master cylinder to the passenger side. Lots of advantages to this - primarily that the space where those bits sit in the 19 is a bit of a problem for downpipe clearance and the megane has a much bigger servo which might be beneficial. Potential downsides - Lots of work. Also the 19’s bulkhead is quite flimsy and I think it would need reinforcement to make it stiff enough for this to work satisfactorily.

B - spend time doing lots of bodging to use some of the megane 225 bits with some R19 bits.

C - spend a bit of money and get something from another car that already has a hydraulic clutch integrated to the brake pedal box/servo assembly and hopefully have to only do some minor mods to fit.

Oh, one more option - spend loads of time pissing around on option B, before finally accepting defeat and going with option C.

The cable clutch pedal on the 19 is integrated into the pedal box, with a single pivot bar running through both the brake and clutch pedals.

19 pedal box removed on the right, megane hydraulic clutch pedal on left

The idea was to get the megane hydraulic clutch pedal and the 19 pedal box to work together by chopping off the side of the 19’s pedal box that carries the clutch pedal, to sit the megane clutch pedal in a suitable position next to it. A lot of cutting and grinding - the megane clutch pedal in particular suffered badly. This was in preference to trimming anything much off the brake side of the pedal box. Reason being that I’m not keen on any modifications that depend on the quality of my welding to be strong enough to ensure safety. So cutting and re-welding of critical brake bits is out.

I spent quite a bit of time on this and got to something that looked like it had potential, if I cut and re welded the clutch pedal arm itself to reposition the foot pad

The problem is that the aperture in the 19’s bulkhead for the pedal box backplate is really quite small (I think it’s the same as the R9 /11?) and it fits from the engine bay side so all the bracketry and pedals have to pass through. So 2 problems:

1 - The assembly would be too big to go through the hole and even if it did

2 - The megane clutch pedal gubbins wouldn’t clear the steering column.

No go.

So… plan B. What else uses a hydraulic clutch that I could potentially pinch bits or an entire pedal box off?

Turns out if I want to stick to the Renault parts bin it’s either the mk2 clio dCi 100, the mk1 megane scenic RX4 (the 4x4 one - all other mk1 scenics have a cable operated clutch) or various Lagunas. All mk2 meganes and mk2 scenics use the same bits as the 225 and the Laguna bits look massively different and unlikely to fit. Looking at photos of the clio and RX4 pedal boxes on ebay, it looked to me like the RX4 one would be most likely to be successfully modified but there was only one on ebay and it was just the bare pedal box without all the other little bits and bobs that might be useful. So another scrappy scavenger trip was required.

Had to find an RX4 which already had the engine removed, to give me space to get all the bits I wanted from the engine bay side. Took a while to find one but got to this one just before its turn to be crushed.

Side note - these cars use drive by wire throttle, but this is done by a mechanical cable from the pedal to a throttle pot mounted in the engine bay which can be seen in the photo below. Is that not the daftest setup you've ever seen?

Lot of contortion in the footwell getting this bloody thing out

That was fun.

And here’s the lovely bounty from that trip.

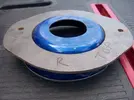

Got the complete pedal box, master cylinder, servo, fluid reservoir and some remote reservoir pipework that might come in handy, all for a few quid. Clearly the pedal box back plate on the RX4 is slightly larger than the 19’s one.

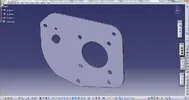

Thought about cutting off the RX4 pedal box backplate and waterjet cutting a new 3mm backplate to the shape of the 19's one.

Didn't bother with that in the end as I decided I'm not turning back now anyway so just butcher the 19’s pedal box to remove the original backplate and use that, which should allow the assembly to bolt straight into the car. So I chopped away most of the bracketry off the 19 pedal box to allow me to get in with a spot weld drill and remove the rest of it cleanly.

Did the same from the other side on the RX4 pedal box (so that the backplate has the spot weld removal holes and not the pedal bracket) then a bit of trimming on the feet and bingo, all fits together.

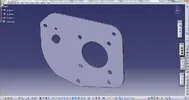

Little bit of trimming at the base of the bracketry to allow it to pass through the bulkhead aperture and clear the folded return and we’re in business.

Next problem - The scenic servo is bigger than the 19’s one and won’t fit the 19 <sigh>.

So now I needed to make the 19’s servo work with my hybrid 19/RX4 pedal box . Main issue is that the clevis/fork thing on the end that the pedal pushes on has a much shallower slot on the 19’s servo. So I had to cut some little chunks out of the RX4 pedal to clear it.

Also the pivot hole is further out. Luckily the end on the 19’s servo is threaded so I just wound it down as far as it could go which luckily was just far enough. Trimmed the extra length off the end of the rod to clear the pedal again.

Playing nice with the steering column. Good to go.

Getting to a workable solution for this took a lot more time and effort than it had any right to.

Three options:

A - Fit all the pedals from the Megane - including the brake transfer bar, relocating the servo and master cylinder to the passenger side. Lots of advantages to this - primarily that the space where those bits sit in the 19 is a bit of a problem for downpipe clearance and the megane has a much bigger servo which might be beneficial. Potential downsides - Lots of work. Also the 19’s bulkhead is quite flimsy and I think it would need reinforcement to make it stiff enough for this to work satisfactorily.

B - spend time doing lots of bodging to use some of the megane 225 bits with some R19 bits.

C - spend a bit of money and get something from another car that already has a hydraulic clutch integrated to the brake pedal box/servo assembly and hopefully have to only do some minor mods to fit.

Oh, one more option - spend loads of time pissing around on option B, before finally accepting defeat and going with option C.

The cable clutch pedal on the 19 is integrated into the pedal box, with a single pivot bar running through both the brake and clutch pedals.

19 pedal box removed on the right, megane hydraulic clutch pedal on left

The idea was to get the megane hydraulic clutch pedal and the 19 pedal box to work together by chopping off the side of the 19’s pedal box that carries the clutch pedal, to sit the megane clutch pedal in a suitable position next to it. A lot of cutting and grinding - the megane clutch pedal in particular suffered badly. This was in preference to trimming anything much off the brake side of the pedal box. Reason being that I’m not keen on any modifications that depend on the quality of my welding to be strong enough to ensure safety. So cutting and re-welding of critical brake bits is out.

I spent quite a bit of time on this and got to something that looked like it had potential, if I cut and re welded the clutch pedal arm itself to reposition the foot pad

The problem is that the aperture in the 19’s bulkhead for the pedal box backplate is really quite small (I think it’s the same as the R9 /11?) and it fits from the engine bay side so all the bracketry and pedals have to pass through. So 2 problems:

1 - The assembly would be too big to go through the hole and even if it did

2 - The megane clutch pedal gubbins wouldn’t clear the steering column.

No go.

So… plan B. What else uses a hydraulic clutch that I could potentially pinch bits or an entire pedal box off?

Turns out if I want to stick to the Renault parts bin it’s either the mk2 clio dCi 100, the mk1 megane scenic RX4 (the 4x4 one - all other mk1 scenics have a cable operated clutch) or various Lagunas. All mk2 meganes and mk2 scenics use the same bits as the 225 and the Laguna bits look massively different and unlikely to fit. Looking at photos of the clio and RX4 pedal boxes on ebay, it looked to me like the RX4 one would be most likely to be successfully modified but there was only one on ebay and it was just the bare pedal box without all the other little bits and bobs that might be useful. So another scrappy scavenger trip was required.

Had to find an RX4 which already had the engine removed, to give me space to get all the bits I wanted from the engine bay side. Took a while to find one but got to this one just before its turn to be crushed.

Side note - these cars use drive by wire throttle, but this is done by a mechanical cable from the pedal to a throttle pot mounted in the engine bay which can be seen in the photo below. Is that not the daftest setup you've ever seen?

Lot of contortion in the footwell getting this bloody thing out

That was fun.

And here’s the lovely bounty from that trip.

Got the complete pedal box, master cylinder, servo, fluid reservoir and some remote reservoir pipework that might come in handy, all for a few quid. Clearly the pedal box back plate on the RX4 is slightly larger than the 19’s one.

Thought about cutting off the RX4 pedal box backplate and waterjet cutting a new 3mm backplate to the shape of the 19's one.

Didn't bother with that in the end as I decided I'm not turning back now anyway so just butcher the 19’s pedal box to remove the original backplate and use that, which should allow the assembly to bolt straight into the car. So I chopped away most of the bracketry off the 19 pedal box to allow me to get in with a spot weld drill and remove the rest of it cleanly.

Did the same from the other side on the RX4 pedal box (so that the backplate has the spot weld removal holes and not the pedal bracket) then a bit of trimming on the feet and bingo, all fits together.

Little bit of trimming at the base of the bracketry to allow it to pass through the bulkhead aperture and clear the folded return and we’re in business.

Next problem - The scenic servo is bigger than the 19’s one and won’t fit the 19 <sigh>.

So now I needed to make the 19’s servo work with my hybrid 19/RX4 pedal box . Main issue is that the clevis/fork thing on the end that the pedal pushes on has a much shallower slot on the 19’s servo. So I had to cut some little chunks out of the RX4 pedal to clear it.

Also the pivot hole is further out. Luckily the end on the 19’s servo is threaded so I just wound it down as far as it could go which luckily was just far enough. Trimmed the extra length off the end of the rod to clear the pedal again.

Playing nice with the steering column. Good to go.

Last edited: